There are a few scenarios where the advertised protection a process offers are effectively worthless — Ebay disputes won’t refund shipping charges or require you to pay additional shipping to return an item, so shorting the customer by less than the shipping cost makes winning your dispute worthless. The 1970’s Fair Credit Billing Act gives you the right to dispute charges up to 60 days after the charge — but, when I ordered a CSA membership in September that started the following March … that window precluded a simple charge-back when the CSA claimed I was not on their list. I expect this window is why people get upset when companies finalize the charge before shipping the product.

Outside of the FCBA contest period, there’s not a whole lot you can do. Small claims could be a route, but that is less effective for inter-state transactions. Some company in Texas doesn’t really care that they’ve got a judgement against them in Ohio. Ohio doesn’t have a lot of power to force payment, either. Traveling to the state with more direct jurisdiction is expensive, and you’re not likely to reclaim damages incurred in obtaining the judgement (i.e. the settlement is not apt to cover your hundred dollar refund, three hundred dollar plane ticket, thousand dollars in hotel charges, and couple hundred bucks for a rental car).

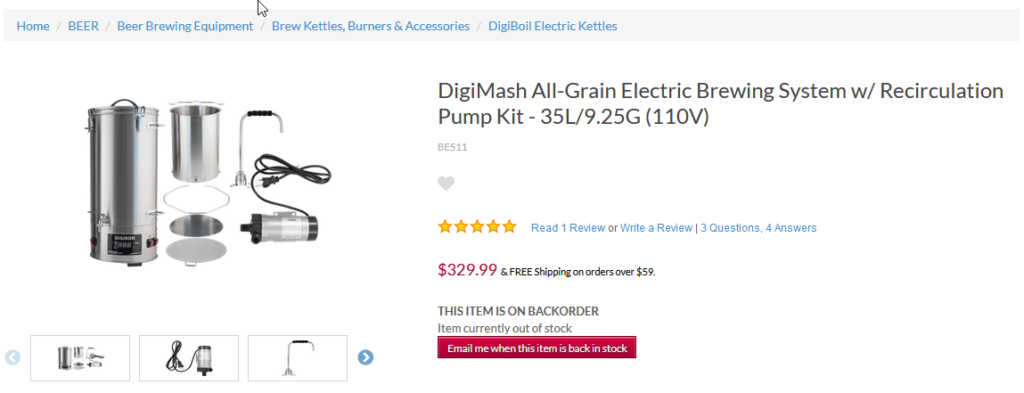

That’s where we were with Keg Factory. We’d gotten a DigiBoil with an inaccurate temp reading. And been told by KegLand, the manufacturer, that the unit isn’t meant for mashing so isn’t designed to have an accurate temperature reading. (Asking why there’s a mashing kit for the not designed for mashing product didn’t yield any illuminating answer) … the owner of Keg Factory told us the product didn’t seem to be a good match for our needs (true, but the advertised function of the product certainly met our requirements!) and offered a shipping label to return the thing. Seemed like a good idea to stop wasting time on a product if the manufacturer says it’s not good enough for its intended purpose. We confirmed they weren’t looking to add a restocking fee or otherwise charge us — a full refund was what was on offer. Yup, that’s it. So we packed up the thing, shipped it off, and confirmed delivery. That was March. We proceeded to contact them looking for our refund. Calls routed to voicemail. No return e-mails. Online chat where we’re the next in queue for hours. When we did get through to someone, we’d be told someone would look at it that day. And still no refund.

As a last ditch effort, we filed a complaint with the Better Business Bureau. The Austin office concurred that our problem fell into their purview and forwarded the complaint on to the vendor. We got a refund notice within a few hours! It took a few days for the refund to clear through to my credit card, but a complaint with the BBB accomplished in three or four days (days where we didn’t do anything) than months of calls / online chats / e-mails managed. Sad that it seems to take publication of poor service to correct a problem … but I’m exceptionally glad to have this saga over.